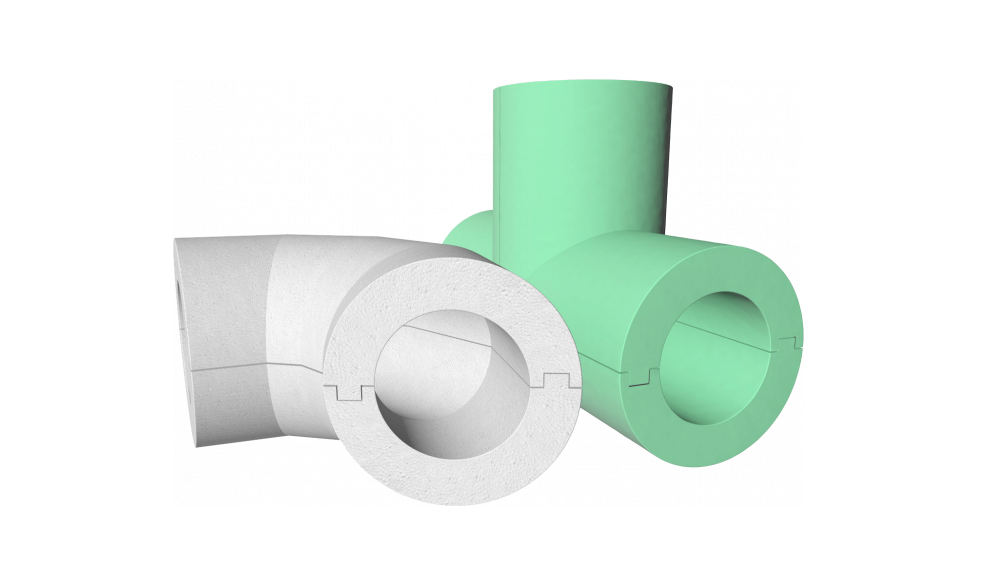

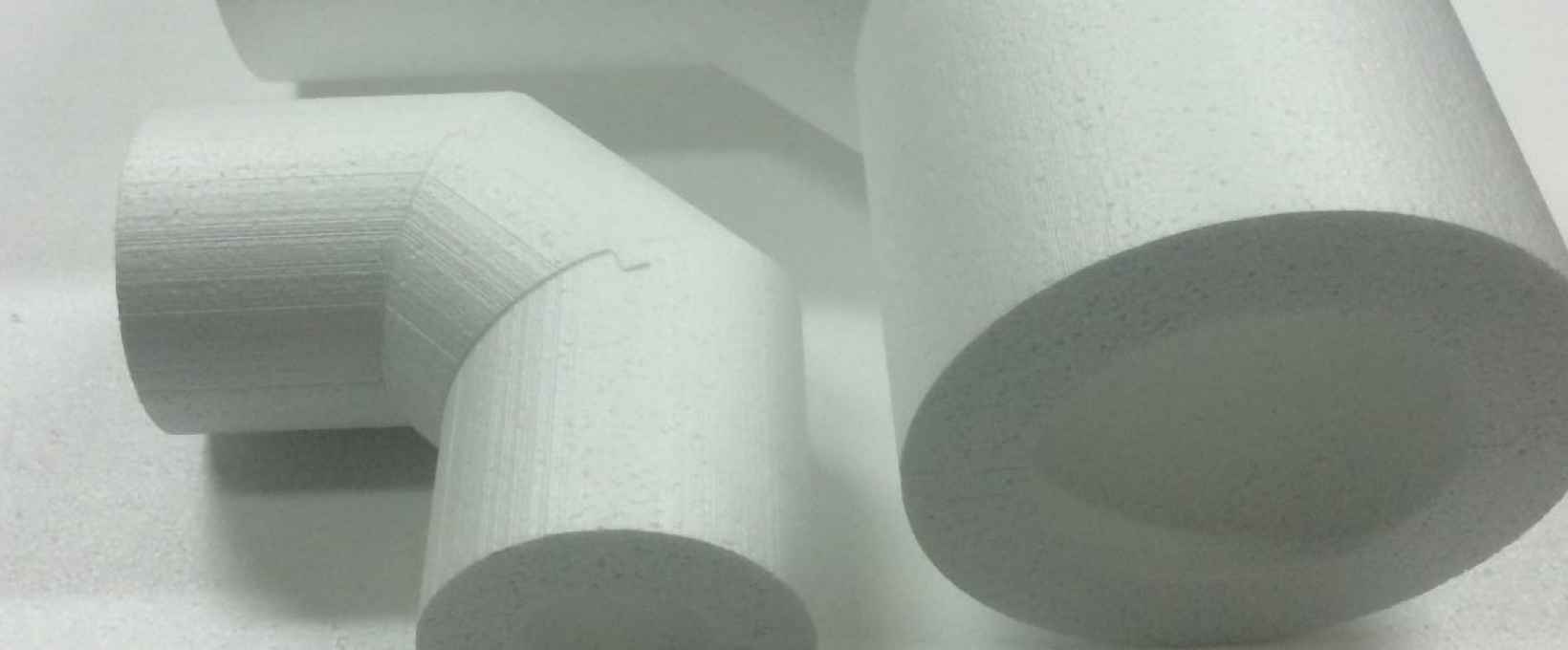

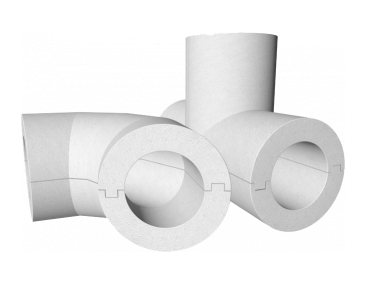

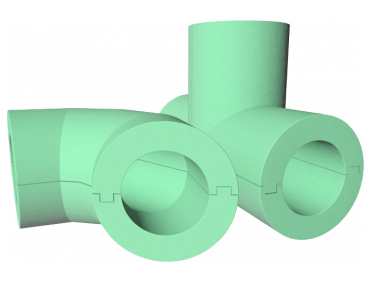

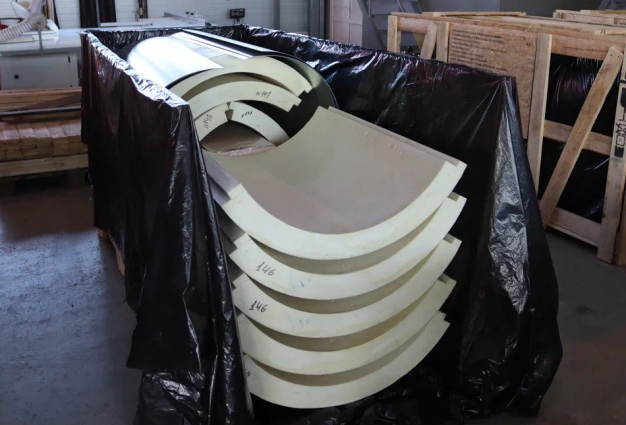

Fittings of polystyrene foam (elbows, tees) are segments for thermal insulation of pipeline bends or branches.

These products are made for pipes with a diameter from 32 to 1420 mm.

Products of polystyrene foam have a low weight and low cost in comparison with other heat-insulating materials.

Styrofoam fittings are usually supplied uncoated.