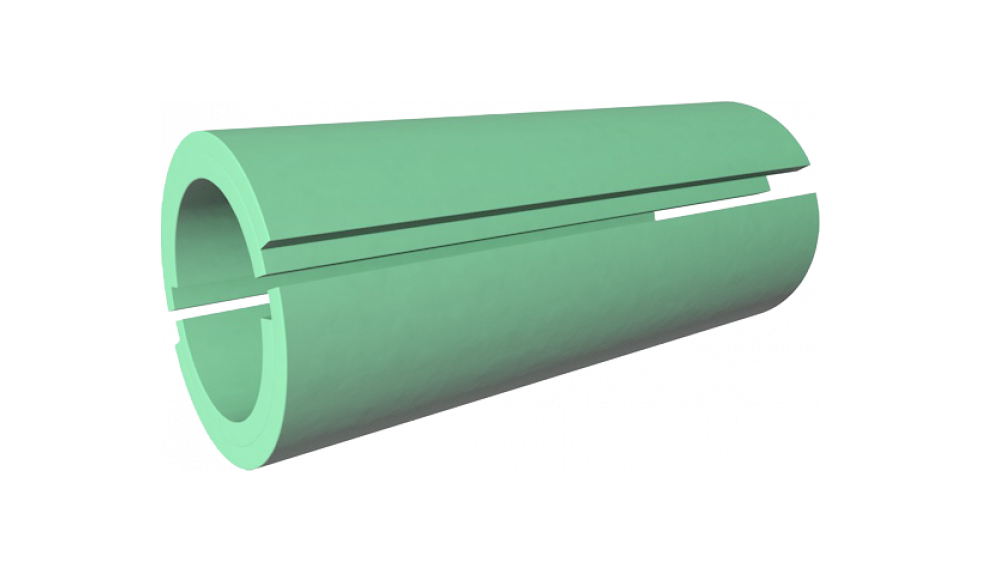

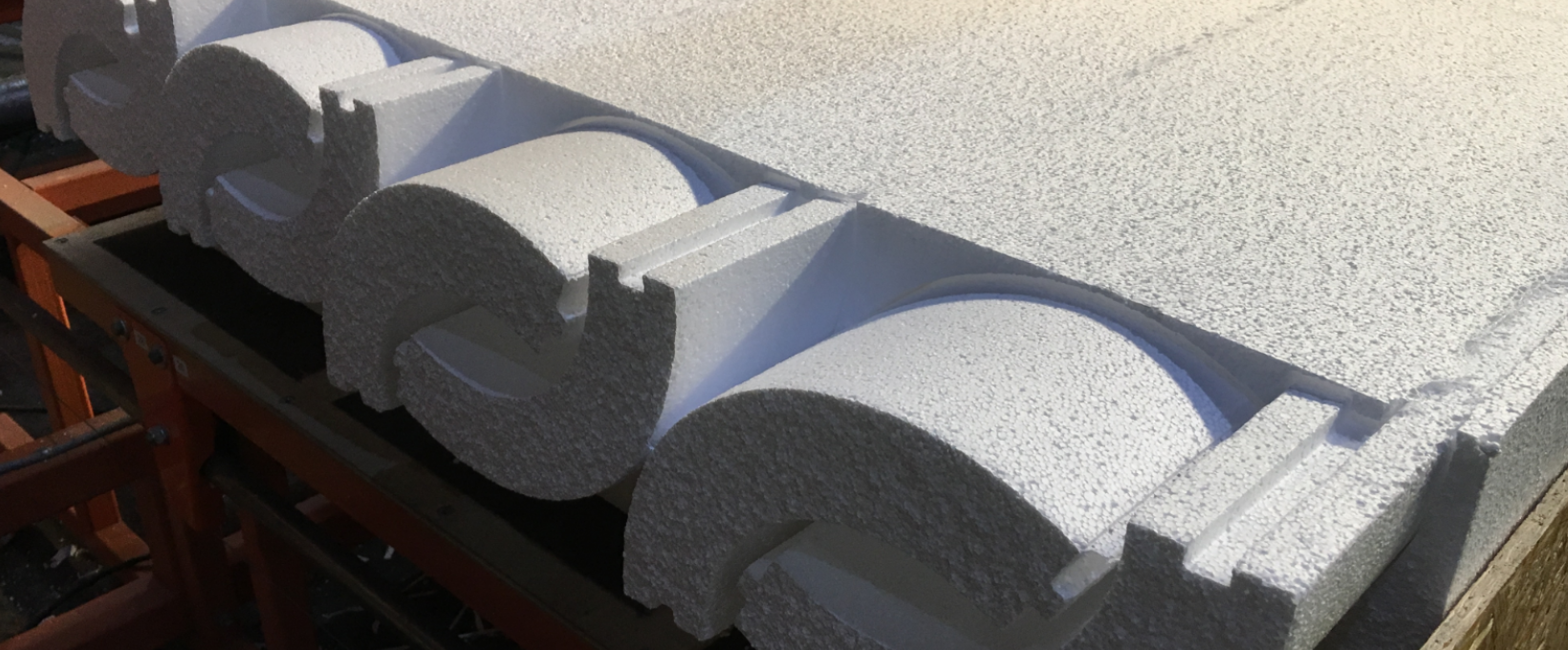

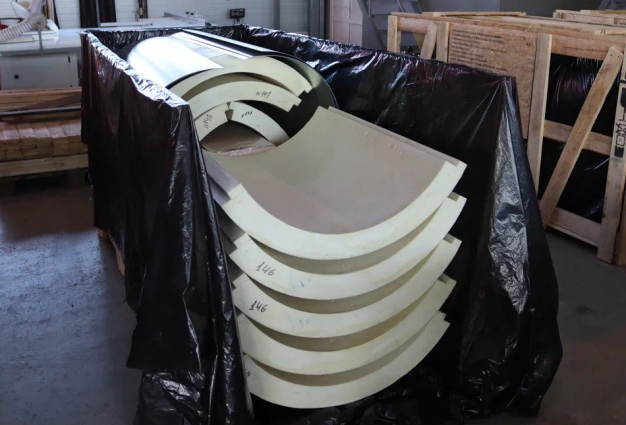

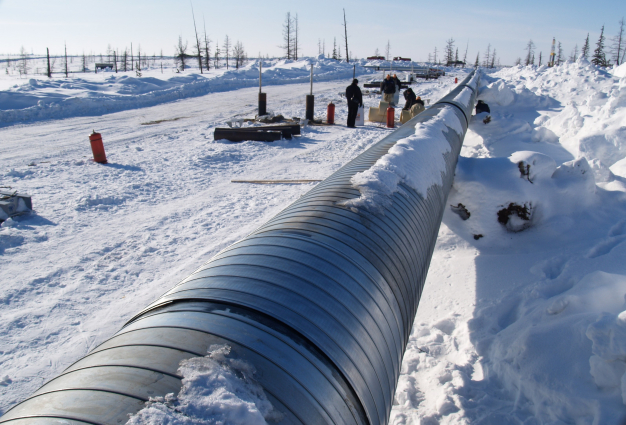

Less expensive insulation solutions for straight sections of pipelines use shells of polystyrene foam.

Depending on the production technology, polystyrene foam can be divided into 2 types: pressed and extruded.

When choosing foam polystyrene as thermal insulation one should consider that it is cheaper, but not as strong as polyurethane foam.

Temperature range of use expanded polystyrene -50 to +70°C.

PS foam shells are available in various lengths for pipes with diameters from 32 to 1420 mm.